The HEMTT in brief

The Heavy Expanded Mobility Tactical Truck (HEMTT) is a family of 8x8 diesel-powered, off-road capable military trucks used primarily by the United States Army. Built by Oshkosh Corporation, the HEMTT has been in service since the early 1980s and plays a crucial logistical role in transporting ammunition, fuel, cargo, and equipment across difficult terrain in support of frontline units.

M978 tank truck, Beatty, Nevada

M978 tank truck, Beatty, Nevada

Thes vehicles were designed for high mobility in harsh conditions (mud, sand, snow) and to be frequently used in combat support, logistics, and recovery, as well as to operate in NBC (nuclear, biological, chemical) contaminated areas. There were many variants equipped with armored cabs for crew protection in combat zones. The are powered by Diesels, Caterpillar or Detroit Models, with an Automatic Transmission. They have a payload capacity around 10 tons, varies by variant for a range of c300 miles (480 km) and a top Speed of c60 mph (97 km/h).

Common Variants includes the following;

- M977 Cargo Truck

- M978 Tanker (fuel delivery)

- M983 Tractor (used for towing PATRIOT missile systems)

- M984 Wrecker (recovery vehicle)

- M985 Cargo with Material Handling Crane

- M1120 Load Handling System (LHS) for fast container and cargo handling

They were upgraded, with the A3/A4 models featuring improved armor, engine efficiency, and load systems, itegration with CROWS (Common Remotely Operated Weapon Station) for defense. They were better geared towards the Army's Palletized Load System (PLS) logistics modernization efforts.

Development History

In the years following the cold war, especially the 1970s, the US Army was found stuck with a large park of M35 and following-up classic 6x6 medium to heavy trucks, of the classic "long bonnet type". Familiar, they were still in the lineage of WW2 6x6 medium trucks, legends such as the "Jimmy" (GMC CCKW) and others. In between, if the needs of the army did not evolved radically, the park was rapidly ageing. There still many 1950s legacy vehicle around like the Dodge M37, Reo (and others) M35 and M39, Mack M123/125, and their modern reinterpretations, the M809 series of the 1970s and in 1982 appeared the very last of the "long bonnet" types, the M939.

However the success obtained by the COE types in Europe, notably from Austria and Germany, in particular the MAN series was due mostly to a mare rational layout placing vibility and handling above all else consideration. This, and many mechanical innovations mde these vehicle attractive as a replacement for the 1950-60 park, that was going to be transferred to the National Guard before being sold to the civilian market. The specifics of US Army procurement (and for all branches in general) led to a write-off of a direct purchase of sch vehicles in Europe. Instead, the US Army launched a competition for a new family of 8x8 COE tactical trucks.

Ford M656 8x8 Vietnam-ear COE tactical truck. Used to carry and operate the Pershing missile system.

Ford M656 8x8 Vietnam-ear COE tactical truck. Used to carry and operate the Pershing missile system.

The Army did not started blind on this. Already some experience was gained in the Vietnam War with a 8x8 COE truck already, a bit forgotten today, the Ford M656. This 5-ton 8x8 military truck that was produced for cargo transport, designed to be able to carry heavy loads over rough terrain, powered by a Continental AVDS-1790-2A eight-cylinder diesel engine rated for 450 horsepower, mated to an Allison MT654CR six-speed automatic transmission and a two-speed transfer case, allowing the driver to select either two-wheel or eight-wheel drive.

It was eventually phased out of military service in the 1990s, but mny ended on the civilian market. Produced by Ford in 1968-69 it was made into 3 versions, but was dedicated to use the Pershing 1a missile. Not a failure, it was seen as a specialized vehicle for the Pershing and XM543E2 program, but its testing ended in 1964. There was still some reluctance to adopt the formula at the time.

However in 1980, the US Army agreed over specifications for a famliy of 8x8 COE general utility heavy trucks, inspired by what was done in Europe. With the evaluation of proposals submitted by AM General, MAN, Pacific Car & Foundry (PACCAR) and Oshkosh Truck Corporation competing, providing prototypes. It soon appeared PACCAR–GMC (the natural leader) had aleady won the competition in 1981, and a pre-production assembly line already established. But in May 1981, there was a complete reversal: The U.S. Army Tank-Automotive Command decided instead to award an initial five-year contract valued at US$251.13 million, to Oshkosh Truck Corporation instead. This was for the production of the 10-short-ton (9,100 kg) 8×8 vehicles under a programme calling these "Heavy Expanded Mobility Tactical Truck" (HEMTT). PACCAR appealed of the decision and its lawyers roamed the Pentagon, but for no avail. Oshkosh, the underdog, had just won one THE most important military truck produrement program of the last two decades.

About Oshkosh

Oshkosh Corporation was still not a newcomer. It was founded in 1917, based in Oshkosh, Wisconsin, and grew as a global industrial technology company designing and manufacturing purpose-built vehicles and equipment, with operations spanning three main segments:

-Access Equipment – aerial work platforms and lift equipment (JLG, Jerr-Dan)

-Defense / Transport – tactical military vehicles and trailers (formerly the “Defense Segment”)

Vocational & Commercial – vehicles like refuse trucks, concrete mixers, airport products (McNeilus, Pierce)

Today the company comprises c15,000–18,000 employees 125 facilities across 24 countries, for 130–150 markets. It's a globe-spanning business.

The company over time acquired JLG, Jerr-Dan (access/lifting equipment), Pierce (fire apparatus), McNeilus (refuse trucks), Pratt and Miller (acquired 2020, robotics/defense). Oshkosh Defense (APK/LTVs, heavy tactical vehicles) is perhaps the best known. Its trucks saw action for decades in Iraq and Afghanistan, and the company also won important contracts for replacement vehicles, IED and mines protected armoured trucks and cars to replace the Hummer. More recently, Oshkosh puts a strong emphasis on sustainability, social responsibility, and ethical governance and by June 2025, released their 2024 Sustainability Report, highlighting progress in emissions reduction, waste management, and community engagement. On Investor Day (June 5, 2025) Its outlook framed around solid revenue growth, margin expansion, and financial targets through 2028. Recently the “Defense Segment” was rebranded to “Transport Segment” now headed by Steve Nordlund from July 14, Keith Allman as Chair of the Board from May 2025. The company inaugurated a brand new offer at CES 2025 with electric and autonomous vehicles—including EV postal trucks, garbage trucks, fire apparatus, and AI-powered refuse collection robots.

Production History

1st Contract 1982-87

The first prototype HEMTT was completed in December 1981, followed by pre-production models by March 1982. The first production vehicle rolled of the line by September 1982. Production was spread over five contract years, 2,140 vehicles total, with options for an additional 5,351 HEMTTs, grand total 7,490 vehicles. The options were later exercised. The HEMTT soon became the "hottest" military trucks in US inventory at the end of the cold war and started to replace the oldest M35s still around.

3 Others contracts, 1987-2001

-The second HEMTT contract was awarded to Oshkosh again in April 1987, calling for a base of 1,403 vehicles, with options for 1,684 more, and again all these were exercised.

-A supplemental agreement was signed in April 1989 for a further 1,449 vehicles, plus an option for 363, in a second HEMTT, and option was exercised again.

-The third production contract was awarded mid-1994 with deliveries of c14,000 HEMTTS to compete the replacement schedule of leacy cold war vehicles.

The fourth contract was awarded in August 1995, extending production until September 2001.

FHTV Contracts

The Family of Heavy Tactical Vehicles (FHTV) contract was awarded to Oshkosh as well, by the U.S. Army in March 2001. It covered the M1070 HET, M1074, and M1075 Palletized Load System (PLS) trucks as well as their M1076 PLS trailers. In all, 5,398 trucks and 1,100 trailers, options comprised. The FHTV production succeeded to the HEMTT from March 2001 and went on until mid-fiscal year 2006 (FY06).

After the new budget reductions of post-cold war years, and "dividends of peace", the FHTV contract was extended and renegotiated. By February 2007, Oshkosh announced a new contract to continue production of FHTV with the FHTV 2 contract covering also the new production of the new HEMTT A4, from mid-2008 as well as PLS vehicles and PLS trailers. In total 2,173 new-build HEMTT A4, 104 refurbished HEMTT A4 from A2s.

Production of improved HEMTT A2s was continued until production ready tp swap to the HEMTT A4, from July 2008 onwards, except for the M1977, remaining under A2 configuration for fleet commonality, until replaced in turn by the M1977A4. In October 2008 the FHTV 3 contract (US$1.2 billion) was announced signed by TACOM, 6,000 vehicles and trailers under three years, both A4 and A1 models of the PLS and HET plus "recapitalized" (Recap) vehicles, generally A2 ported to A4 standards. HEMTT A4 were now under the new US Army Long Term Armor Strategy (LTAS) program, they needed to be compliant to a new standard of upgraded suspensions and integral composite (A-kit) armor, prepared for rapid intsllation in the field of B-kit appliqué armour if needed. By late-2009, 11,500 HEMTT A4s (new-build and Recap) were ordered under FHTV 2-3 contracts.

The FHTV 4 contract was announced in 2012, under abridge contract revised in October 2013, under a 5 yars contract provisioned by US$822 million to ensure production would stay active without break. Under the same contract, on 19 June 2015, Oshkosh Defense announced a new 5-years contract for $780 million to Recapitalize (Recap) earlier FHTV vehicles, an estimated 1,800 FHTVs and around 1,000 new production PLS trailers. HEMTT would comprise around 75% of the Recap potential, all done solely at Oshkosh FY 2019. In March 2016, Oshkosh received $430 million for the Recap of 1212 HEMTTs/PLS, and 345 new-build trailers to ebe delivered 2016–2017.

In April 2017, Oshkosh announced $258 million Recap contract for 670 FHTVs and 356 newbuilt PLS trailers, t be delivered from December 2017. On 23 May 2018 Oshkosh announced a $235.2 million for the Recap of 410 FHTVs, 680 new built PLS trailers., FY19 and on On 8 February 2019 $225.7 million for the Recap of 407 FHTVs, 601 new PLS trailers also FY19. Then, the final FHTV 4 contract was announced in March 2020 for US$346.4 million both for the U.S. Army and Army Reserve, all Recaps, with delivered for December 2021. On 3 May 2021 a three-year extension to the FHTV 4 contract concerned Recap HEMTT, PLS trucks trailers, HETs, 353 new and recap. HEMTTs for US$130.5 million, US$146.8 million total.

Recapitalized Vehicles

IPS Modernization HEMTT A2-to A4 conversion

IPS Modernization HEMTT A2-to A4 conversion

Under this term, the same program applies that already concerned M1 Abrams and M2/M3 Bradley. Used vehicles are returned to Oshkosh, stripped to their frame rails, fully rebuilt to a 0-hour, 0-mile, brand new condition. This implies the chassus are sandblasted, then recoated and repainted anew. Re-assembly is done on the base of all new components or completely refurbished ones. Entire sub-assemblies are new built and the hull is often made of new materials and new structures to accomodate the optional armor kits A and B. The suspensions, engines, gearbox and all linked mechanical parts, down to the smallest dashboard item (which is also new) are changed and the vehicles are tested before delivery. This is done on the same production line as new vehicles, so the end performance tests and inspection are identical. Recapitalized vehicles are under the builder's full warranty with rare new additions such as air-conditioning and the new armor-ready cabs as well as all sorts of electrical upgrades, plus a new anti-lock braking system.

Design of the HEMTT

General caracteristics

The HEMTT was a 8x8 chassis for heavy transport capabilitiesn carry or resupply both combat vehicles or heavy weapons systems. They were intended to replace the former 5-ton trucks in service, offers a baseline 10-tons payload and better mobility, better visibility thanks to the COE (Cab Over Engine) configuration. The base HEMTT chassis is of a ladder type, with early wheelbase extension of needed, and modular to support a large variety of configurations, with the base cargo, tanker, tractor and wrecker.

The HEMTT was developed as a tactical truck with excellent mobility on all terrains, helped by the 8x8 configuration, yet made cheaper by the use of COTS (Commercial off the shelf) components as well as militarized commercial automotive components wherever possible, notably for the engine and transmission. Some components were shared with others vehicles in the Oshkosh Logistics Vehicle System (LVS) vehicles used by the U.S. Marine Corps at the time.

Apart the M984 wrecker variant (254 × 89 × 9.5 mm, front; 356 × 89 × 9.5 mm, rear), all HEMTT variants used the same chassis, 257 × 89 × 9.5 mm. It was heat-treated with carbon manganese steel, with a yield strength of 758 MPa. Bolted construction was used for easy transportation and parts maintenance and repairs, with Grade 8 bolts. They all came also with at least fixtures for a centrally mounted self-recovery winch, which was indeed mounted on 20% of production. The winch is a simple type with the same capacity as the vehicle unladen, powered by the main engine.

Compared to "long bonnet" models, the HEMTT is caracterized by its two-door forward control cab, with two seats, two windscreens. The cab is made of heavy-duty welded steel for the framing, wrapped in corrosion-resistant sheet metal skin from Simula Inc.

Powerplant & Mobility

Below and forward of the cab is located the beating hart of the HEMTT: A Detroit Diesel 8V92TA V-8, two-stroke diesel, rated for 445 hp (332 kW). It is common to the early 1982 HEMTT A0 and A1 models. The A2 had the upgraded DDECIV version. The A4 is now provided the EPA 2004 compliant Caterpillar (CAT) C-15 six-cylinder, 15.2-liter diesel rated for 515 hp (384 kW).

As for the gearbox, the early HEMTT A0 and A1 are fitted with an Allison HT 740D 4F/1R automatic transmission with a torque converter as well as the Oshkosh 55,000-pound (25,000 kg) two-speed transfer case. The A2 were upgraded to the Allison HD 4560P 6F/1R automatic transmission. The A4 now sports the Allison 4500SP 5F/1R automatic transmission, but with the uprated Oshkosh's 55,000-pound (25,000 kg) two-speed transfer case.

All HEMTT's front axles are single-reduction Oshkosh 46K. The rear uses a Dana single-reduction with various configurations. Drive to the front axles can be selected, with all axles having differential locks.

The A0/A1/A3 suspension is provided by Hendrickson leaf springs, with equalizing beams. On the A4 models it was upgraded to Holland air suspension, with load rating on the rear axles, but this varies by configuration.

Tires in standard are military types 1600 R20 with a standard tire fit Michelin XZL. They are not of the run-flat type and had no asociated central inflation system.

As for performances, the HEMTT is not amphibious on the sense it could not float, but fording water crossings up to 48 in (120 cm) deep. Tested it was proven to climb a gradient of at least 60%. For tactical mobility, as pure 8x8 they are able to tackle sand, mud and snow, knee deep. They are also air transportable in the C-130 Hercules and C-17 Globemaster. Today's A4 uses a power-assisted on steering, and are able to reach 62 mph (100 km/h) on road, for a range of 300 mi (483 km) loaded, probably around 800 km unladen.

Armament

HEMTT Pershing, 1986

HEMTT Pershing, 1986

The base truck in unarmed, except for he crew's own personal weapons. However the HEMTT A4 came out with not only optional armour on two grades, but also an optionally mounted combat module, with a machine-gunner's post, generally for a standard M2HB heavy machine gun, and a turret-like protection. But some variants of the HEMTT are also weapons carriers, and thus, could count as combat vehicles on their own right. Let's cite for example the HEMTT Phalanx, carrying a naval CIWS for close-in organic defence against helicopters or missiles. The war in Iraq and Afghanistan in the 2000s also raised concerns about ambushes on supply lines to FOBs, leading to a recreation of Vietnam "gun trucks", with improvized add-on armour and extra armament in the flatbed, for convoy escort. The most often transformed "the mad max way", were M977 cargo vehicles. Let's cite also programs such as the NSM anti-ship missile carrier, USA M983 Hemtt Tractor with Pershing II Missile Erector Launcher, and of course the man carrier for the MIM-104B Patriot SAM. They will be treated in time.

Protection

HEMTT M1120A4 with B-kit configuration

HEMTT M1120A4 with B-kit configuration

Simula Inc. was acquired by Armor Holdings 2003, now in BAE Systems. The company, which already produced the cabs, provided some 186 add-on cab armoring kits for use in ex-Yugoslavia in the 1990s (they were never mounted). This was the first of many armouring attempts of the truck, which remains at the core a soft skin truck. From 2004, these kits were used in Iraq. BAE systems supplied by late 2006, some 3600 kits for the Oshkosh HEMTT and PLS. The HEMTT A4 cab is slightly larger, on the Oshkosh PLS A1 standard, and made compliant with the U.S. Army's Long Term Armor Strategy (LTAS) requirements: They now can receive either an A or a B-kit armor, mounted on the field in a couple of hours, to match the intensity of combat operations. The A4 also provided a better integral floor armor, with some "Vee" features for blast deflection, semi-suspended seats, plus an integrated mount for a machine gun and a complete gunner protection kit as well as air-conditioning, the latter being a point often asked for in Iraq and Afghanistan.

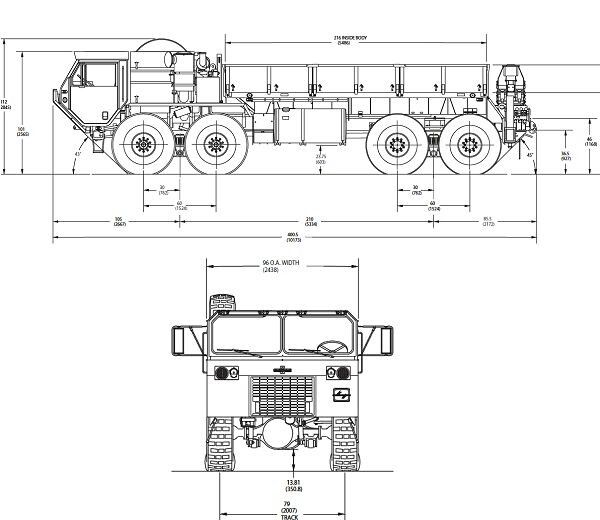

⚙ HEMTT A4 specifications |

| Dimensions | 34 ft 1 in x 8 ft x 9 ft 10 in (10.4 x 2.4 x 3 m) |

| Weight unladen | 42,500 lb (19,300 kg) |

| Weight laden A kit | 69,000 lb (31,000 kg) |

| Weight laden B kit | 75,500 lb (34,200 kg) |

| Maximal loaded weight | 109,000 lb (49,000 kg) |

| Payload | 10 short tons (9,100 kg)+ variable |

| Engine | Caterpillar C15 15.2l, 6-cyl. IWC EPA 2004 diesel 515 hp (384 kW) |

| Transmission | Allison 4500SP 5-speed automatic with Oshkosh 2 speed transfer case |

| Suspensions | Holland ADS-240/246 air ft/rear |

| Steering | Power-assisted on front tandem |

| Performances | 62 mph (100 km/h) |

| Range | 155 US gal (587 L), 300 mi (483 km) loaded. |

| Protection | LTAS compliant, A-kit integral, B-kit add-on appliqué. |

| Armament | RWS, optional cal.05 HMG |

| Crew | 2: Driver, co-driver |

| Tactical Mobility | C130(early), C17(late) and C5 Galaxy |

Variants

Note: More to come as illustrations are completed.

M983

Tractor unit for the trailer-mounted MIM-104 Patriot missile system. Also used with the Interim Stryker Recovery System, and other trailers. An earlier variant fitted with a 30 kW generator and crane behind the cab is the Pershing II Erector Launcher of the CONUS systems, replaced by a M1001 MAN tractor in West Germany at the time.

M983A2/A4

Light Equipment Transporter (LET) tractor mainly used for construction and engineer equipment. 45,000 lb (20,000 kg)) 2 speed hydraulic winch behind the cab to load the trailer but no self-recovery winch.

Operators

Taiwan HEMTT Patriot PAC3

Taiwan HEMTT Patriot PAC3

Bahrain

Brazil: 10x M984 wreckers 2020 (support VBTP-MR Guarani)+ 20 more ordered.

Egypt

Greece

Iraq

Israel: 420 EDA in 2015.

Jordan

Kuwait

Malaysia

Morocco, probably EDA, not confirmed

Oman

Romania: For the Patriot SAM

Qatar

Saudi Arabia

South Korea

Taiwan

Turkey

UAE

United States: All the versios above.

Ukraine: c50 donated with weapons systems.

Bulgaria (in discussions).

Status

Operations, Past and Present

Hemtt in iraq

Hemtt in iraq

(To come)

Future: The CTT Program

In Parallel to the FHTV 4 extension the Heavy Tactical Vehicles (HTV) program was issued on 20 July 2020 with a Request for Information for the "Next Generation Future Truck" (NGFT). Responses were due by 24 August 2020. The program was renamed the Common Tactical Truck (CTT) as replacement for the HEMTT, alongside the PLSA1 and M915 Truck Tractors and haulers. Five variants of the NGFT/CTT are planned, for semi-autonomous or autonomous operations:

-Wrecker to recover the Stryker or MRAPs up to 40 US tons

-LHS Heavy variant with crane to transport flatrack, 16 tons payload

-Tractor operable with the M870, M871, M172, M872, M967 tanker, M1062 tanker, future tanker (8,200 gallons), commercial standard trailers

-Tanker rated for 2,500 gallon or greater.

-Cargo variant with crane, payload of up to 22 tons or greater.